jay@nbdho.com

Small-Batch Headphone Customization: Is It Cost-Effective?

In today’s highly competitive audio market, small-batch headphone customization has emerged as an attractive option for startups, niche brands, and limited-edition product lines. Unlike large-scale manufacturing, small-batch customization allows companies to produce a limited number of units tailored to specific customer preferences. But is this approach truly feasible and cost-effective? Understanding the benefits and challenges can help businesses make informed decisions.

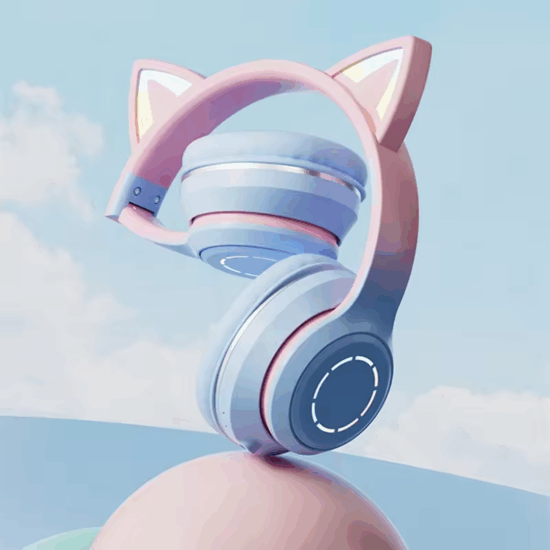

Feasibility is one of the primary considerations. Advances in manufacturing technology, such as 3D printing, CNC machining, and modular assembly lines, have made it easier to produce small batches with significant customization. Many factories now offer flexible production setups that accommodate limited runs without sacrificing quality. This flexibility enables brands to experiment with unique designs, colors, logos, and features that would be prohibitively expensive in mass production.

Cost-effectiveness, however, is more nuanced. Small-batch runs typically have higher per-unit costs due to less economy of scale. Fixed setup costs, such as tooling and design validation, are spread over fewer units, increasing overall expenses. Nevertheless, by avoiding large inventory commitments, companies reduce financial risk and warehousing costs. Moreover, customized small batches can command premium pricing, offsetting higher manufacturing costs.

Another advantage of small-batch customization is speed to market. Without the need to wait for massive production schedules, brands can quickly launch new models or limited editions, responding to market trends and customer feedback. This agility is especially valuable for startups looking to build brand identity or test new concepts.

Challenges remain, including sourcing specialized materials or components in small quantities and ensuring consistent quality across limited runs. Communication with manufacturers is critical to align expectations and confirm that the small-batch process meets standards.

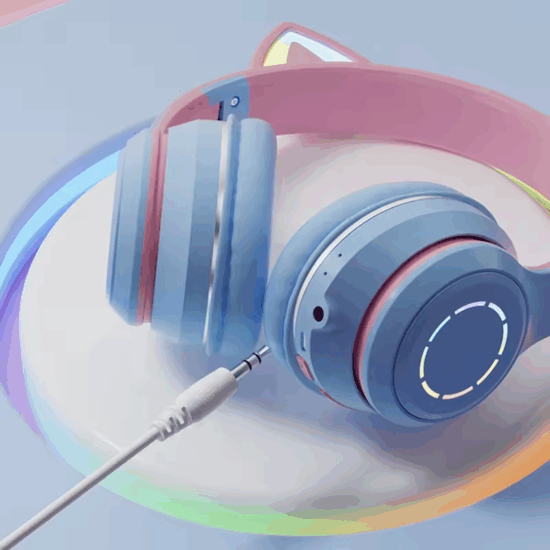

In addition, small-batch customization fosters exclusivity and brand loyalty. Consumers increasingly value unique, personalized products that reflect their identity. Offering custom headphones in limited quantities can create buzz and differentiate a brand in a saturated market.

In summary, small-batch headphone customization is both feasible and cost-effective under the right conditions. With modern manufacturing capabilities and strategic planning, brands can leverage this approach to produce distinctive products, control costs, and rapidly respond to market demands. Careful evaluation of production partners and clear cost analysis ensure small-batch projects deliver maximum value.